Your expert in special materials, sand cores, forging, and charging media!

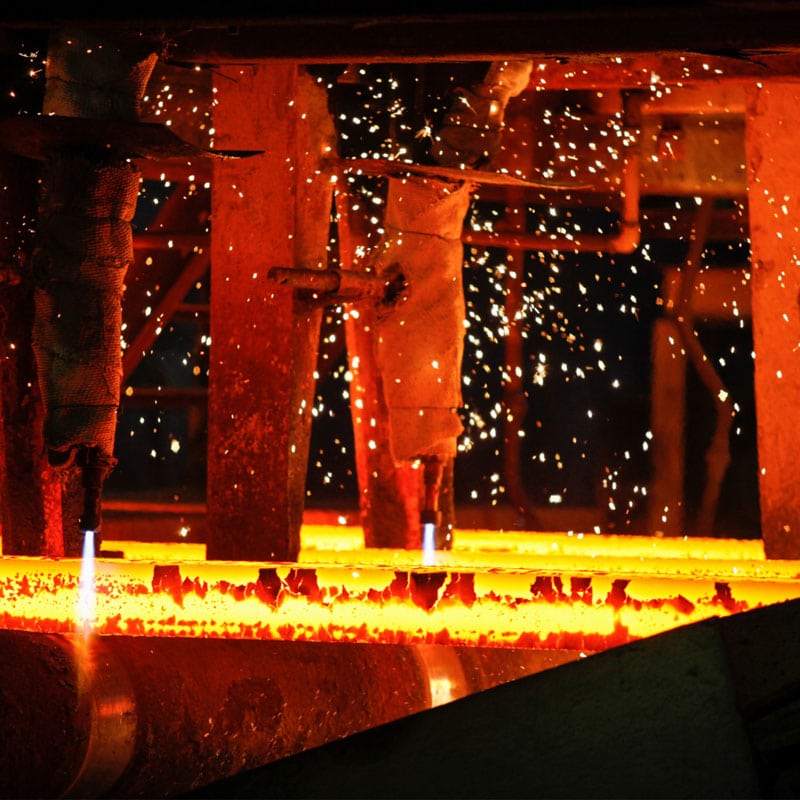

Welcome to OptiSteel GmbH

In a world where precision and innovation are crucial to meeting the growing demands of the industry, we warmly welcome you to OptiSteel GmbH. We understand the importance of special materials, precise sand cores, innovative forging, efficient charging media, and mechanical processing for the success of your projects.

Quick request

OptiSteel GmbH – where special materials lead to extraordinary results

Since our founding, we have aimed to offer our customers innovative and customized solutions that meet their individual requirements.

Our expertise lies in the procurement, development, and provision of special materials that can be used in various industries and applications. Whether aerospace, automotive industry, mechanical engineering, medical technology, or electronics – our special materials find application in numerous highly specialized fields.

What sets us apart is not only the quality of our products but also our commitment to excellent service and customer satisfaction. Our experienced team is at your disposal with expertise, advice, and support to ensure that you receive the best possible solutions for your projects.

As a company, we place great value on innovation, sustainability, and partnerships based on trust and mutual respect. We are proud to collaborate with leading manufacturers and research institutions to always be at the forefront of technology and development.

Our commitment to quality and customer satisfaction drives us to continuously seek new opportunities and improvements to exceed our customers’ expectations.

Thank you for choosing us. We look forward to supporting you in your projects and providing you with our high-quality special materials.

Materials and Products

Special Steels

Duplex Alloys

Austenitic Alloys

Martensitic Alloys

Nickel Alloys

Titanium

Low Alloys

Non-ferrous Metals

Aluminium

Copper

Nickel

Lead

tin

Zinc

Bars

Opti-Steel offers a wide range of bar steel: hot and cold formed round steel.

Discs

We offer discs made of forged steels in various surface finishes, dimensions, and weights.

Sheets

Our high-alloy sheets are distinguished by their special composition and outstanding properties.

Secial Geometries

We deliver special geometries exactly according to your specifications with consistently high quality.

Sand cores

CORE MANUFACTURING USING THE COLD BOX PROCESS

In our production, we use the cold box process on eleven specialized machines to manufacture cores. These are made from a carefully prepared mixture of base sand and resin. The cores vary in size and can be refined with various coatings from our range to meet the specific requirements of our customers.

CORE MANUFACTURING USING THE HOT BOX PROCESS

For the production of our cores using the hot box process, we exclusively use in-house produced, coated sand. These cores are particularly suitable for high-quality cast products and meet the high standards of the casting industry. We specialize in providing the right cores for even the most complex cast parts.

INORGANIC CORE MANUFACTURING

Our inorganic core manufacturing process is based on the use of inorganic materials. An inorganic binder, together with an additive that is either in powder or liquid form, is added to the sand. This mixture features a basic, water-based binder with low viscosity, providing optimal properties for core manufacturing.

Charging Materials – Optimizing Your Heat Treatment Processes

Our charging media are designed for the optimal placement and distribution of goods in the furnace. They enable uniform heat treatment and help reduce cycle times and increase energy efficiency.

Properties

Made from high-quality heat-resistant materials

Customizable to different furnace types and sizes

Durability even at high temperatures

Applications

Hardening

Annealing

Sintering

Other heat treatment processes

Charging Baskets – Efficient and Safe Handling

Our charging baskets are designed to enable efficient loading, transport, and unloading of goods. They are an essential component for the automation of heat treatment processes and contribute to increased productivity.

Properties

Robust construction for heavy loads

Optimal air circulation for uniform heat treatment

Easy integration into existing production lines

Applications

Automotive industry

Aerospace industry

Tool manufacturing

Mechanical engineering

Increased process efficiency

By optimizing heat treatment cycles and improving energy efficiency.

Longer lifespan

Our products are designed to guarantee a long lifespan under extreme conditions.

Customized solutions

Tailored solutions that are specifically customized to meet your requirements and processes.

Expert advice

Our experienced team assists you in selecting the optimal products for your applications.

Forging – Innovation through tradition

We offer a wide range of forgings in various sizes and levels of complexity. From small precision parts to large components, we provide customized solutions tailored to the exact requirements of our customers.

Customized solutions for demanding applications

Consulting & Development

We see ourselves not only as suppliers of special materials but also as active partners in the development and realization of technical projects and assemblies. Our goal is to make your visions a reality with customized material solutions and comprehensive technical support.

Development: From idea to reality

Our team of engineers and material scientists works closely with you to develop innovative solutions for your specific requirements. We use the latest technologies and our deep understanding of special materials to create products that not only meet current standards but exceed them.

Consultation on material selection and application

Support in conception and design optimization

Prototyping and testing to validate product performance

Customization of materials for specific applications

Implementation:

Your projects in experienced hands

The implementation of your projects is carried out by our experienced team, characterized by precision, efficiency, and a high level of technical expertise. We support you from the initial idea to the finished product, ensuring that all aspects of your requirements are met.

Manufacturing of individual parts and assemblies

Quality control and assurance according to industry standards

Assembly and integration of components

Professional documentation and technical support

Your request to us:

+49 (0) 2261 815 9520

info@opti-steel.de

OptiSteel GmbH

Alte Wiesenstr. 12

51580 Reichshof